All Bremi ABS Sensors use the same material as OE along with fit and function. Each Sensor is subjected to an electrical test which compares the sensor data to the OE profile to ensure that it is within optimal range. On top of that, Bremi performs a full thermal shock test that covers a total of 60 cycles to ensure performance under all environmental conditions. Bremi ABS Sensors are exclusively distributed by Karlyn Industries Inc.

TESTING OF BREMI WHEEL SPEED SENSORS

Electrical Test

Sensors are subjected to an electrical test both before and after the thermal shock test.

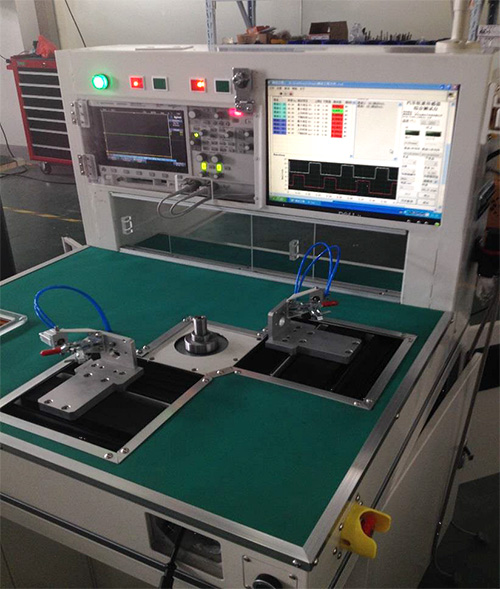

The illustration on the right shows the apparatus used to test the wheel speed sensors.

The following values are recorded and compared to the OE profile to ensure that it is within the optimal range.

- Capacity utilization in %

- Load resistance in Ω

- Frequency in Hz

- VPP (“Volts Peak to Peak”)

Thermal Shock

Within the context of product qualification, all newly produced wheel speed sensors are subjected to defined thermal shock cycles.

Extreme temperatures act on the parts in a special chamber:

- -40°C for a period of 45 min

- +130°C for a period of 30 min

The change in temperature takes about 10 seconds.

A complete test cycle covers a total of 60 cycles.

ABS Wheel Speed Sensor Essentials

The speed sensors at each wheel allow the anti-lock braking system to monitor wheel speed independently. The ABS computer utilizes this information to improve vehicle control under heavy braking especially on loose or slick surfaces. The signals from the systems speed sensors are compared with one another and if one sensor is out of specification, the system can malfunction.

Indication Of Failure

- Illumination of ABS lamp

- Storing of an error code

- Locking of wheels during braking

- Failure of other related systems

Common Causes of Failure

- Mechanical damage to the wheel sensor or cables

- Excessive resistance in the wiring caused by water intrusion, corrosion, dirt and cracks in the wire harness.

- Weak Signal caused by improper gap between the sensor and tone ring along with looseness in the wheel bearing. The Sensors are magnetic and will also attract metallic debris from brake dust, which can adversely affect the signal.

- Corrosion of Tone Ring: Road Salt may get into the hub assembly at the sensor hole and degrade the tone ring

Why choose Bremi Germany Wheel Speed Sensors?

Bremi develops and produces every component of it’s Wheel Speed Sensors in their own factories. Their acquisition of “Streicher Plast” in Germany has allowed them to become a leader in Injection molded parts for electronics and microelectronics. All Bremi ABS Sensors use the same material as O.E. along with fit and function. The final completion and 100% testing of Sensors is done in Germany. Each Sensor is subjected to an electrical test which compares the sensor date to the OE profile to ensure that it is within optimal range. On top of that, Bremi performs a full thermal shock test that covers a total of 60 cycles to ensure performance under all environmental conditions. All Bremi plants as well as all their production process are ISO 2001, TS 16949 certified and a VW A-Rating for Bremi.